-

If you are in the market for a new bike, the sheer volume of choice may seem a little daunting. For instance, why would you choose an aluminium road bike over a steel road bike? Or, what's heavier/stronger/more long-lasting, a steel or titanium road bike? In short, it all depends on where you intend to ride and on what surface. Here to help you decide what may fit your needs best is a guide to the CGR family - our most versatile all-road bikes.

-

First of all, What is a CGR?

-

In short, the CGR family falls under the category of all-road bikes. Take the acronym CGR for instance, it stands for Cross, Gravel and Road. And it does exactly what it says on the tin ....bike! The CGR bikes are by far the most versatile in our lineup. As the name implies, the CGR is designed to excel across a whole host of terrains and surfaces. A real jack of all trades, if you like. To provide consistency across the entire range, each model shares exactly the same features. These are:

- A more than generous tyre clearance. Up to 47mm with 650b wheels or 45mm with 700c wheels. This allows the wheel and tyre setup to be tailored to suit a specific terrain, surface or riding style. Or a mix of all three if you prefer!

- Dual wheel compatibility means that 650b wheels can be accommodated to maximise off-road performance or 700c wheels for road riding with a bit of off-road thrown in. The smaller 650b diameter wheel allows bigger air volume tyres to be fitted which cushion the ride when riding on bumpy terrain.

- Discreet mounts at the rear enable a rear pannier rack to be fitted for any luggage carrying duties. Making the CGR a superb all-terrain commuter or light tourer.

- Built-in mudguard mounts enable the fitting of full-coverage mudguards to help fend off the dirt and keep you cleaner.

- Flat mount disc brakes deliver ultimate braking power and control. Helping to bring you to a safe and controlled stop, whatever the conditions or terrain.

- Bolt thru-axles stiffen up the wheel-frame interface to eliminate wheel flex and improve wheel placement. This is essential for disc brakes, where any deviation in lateral wheel movement can cause the disc pads to rub.

- Internal cable routing maintains the clean lines of the bike for a sleek uncluttered finish.

-

What sort of riding are they for?

-

Fit a CGR with narrow, slick, tarmac-specific tyres and you have a fast and capable road bike. One that's more than capable of keeping pace on fast group rides. Swap these out for some big volume semi-slick or knobbly boots, however, and the bike transforms into something else entirely.

It becomes a fast trail charger that's capable of taking on technical singletrack, canal towpaths, root-strewn forest trails or roads and rocky bridleways. The CGR family encompasses a range of frame materials. Below we outline how a particular frame material affects its performance and ride quality.

-

CGR Ti

-

A CGR Ti kitted out Shimano's latest Ultegra Di2 2x12 speed wireless electronic groupset and carbon wheels from LEVEL.

You may find Titanium sometimes referred to as the 'dream' material. The main reason for this is firstly the comfortable ride quality that it offers. Secondly, titanium has the highest strength to weight ratio of any naturally occurring material. In fact, it's difficult to pick out any negatives for this frame material.

But if we really had to, the only drawback that springs to mind is the additional cost. You see, the process of manufacturing titanium frames is extremely challenging. For instance, did you know that the welding has to take place in a vacuum? This process does not come cheap and this extra cost makes this frame more expensive than most.

This extra cost, however, is more than offset by the lifecycle of a titanium frame. Thanks to its incredible resilience and fatigue/corrosion resistance, a high-quality titanium frame can literally last a lifetime.

- Durability - A good quality Ti frame can last a lifetime... literally. Titanium does not degrade, corrode or fatigue. It will also shrug off accidental impacts or crash damage that may result in any other frame being written off.

- Comfort - Similarly to Steel, Titanium has a natural springiness to it that translates into enhanced vibration absorption (compliance). In terms of 'ride feel,' this means that you experience a very forgiving ride while feeling less fatigue than you would on a super-stiff frame.

- Weight - The ride quality of Titanium is almost identical to steel. Yet it is lighter, so you get the same forgiving ride but with more speed for less effort.

- Cable routing - The cables are routed internally through the frame to preserve those beautifully sleek titanium lines while improving its aerodynamic efficiency.

-

CGR SL

-

The CGR SL is shown here in its all-road configuration, with gravel-optimised 1x gearing, Mavic Allroad 700c wheels and 45mm WTB Riddler tyres.

The CGR SL's construction owes much to our Endurance SL series of frames. Much like its road-optimised siblings, it's constructed from a carefully selected blend of Toray T800 and T1000 carbon fibres. Each fibre is layered to an exacting specification using advanced monocoque mould technology.

An EPS inner core system eliminates any excess material on the inside of the frame and, in turn, eliminates any weak spots in the construction. This manufacturing process ensures complete structural consistency throughout. In layman's terms, this means that we can produce a frame with a higher strength to weight ratio.

- Weight - The lightest of the framesets in the CGR family, the lighter weight of a carbon monocoque frame requires less effort to propel it. This is particularly advantageous when climbing or sprinting.

- Stiffness - Carbon is ultra-stiff, which means that laying down the power is much more efficient thanks to the absence of lateral flex. The CGR SL is incredibly efficient at transferring the power generated by the rider to forward motion, with little wasted effort.

- Comfort - A frame that is super-stiff can produce a slightly harsh ride, especially over rough surfaces. With much of the 'road buzz' being transmitted through the frame. To counter this, we have incorporated dropped seatstay technology into the CGR SL's design. The dropped seat stays allow the seat tube/seat post to flex slightly for improved vertical compliance. This resultant compliance that this generates helps to counter the effect that vibrations place on rider fatigue. The capability to fit big volume tyres also helps to provide additional comfort.

- Cable Routing - Wit the optional LEVEL 5 carbon integrated handlebars system fitted, every cable is fully hidden away from the airflow. This generates up to 40% less drag when compared to a traditional handlebar setup. It also makes the bike look oh so nice, with no cables to mar the spectacular lines of this carbon dream machine.

-

CGR 725

-

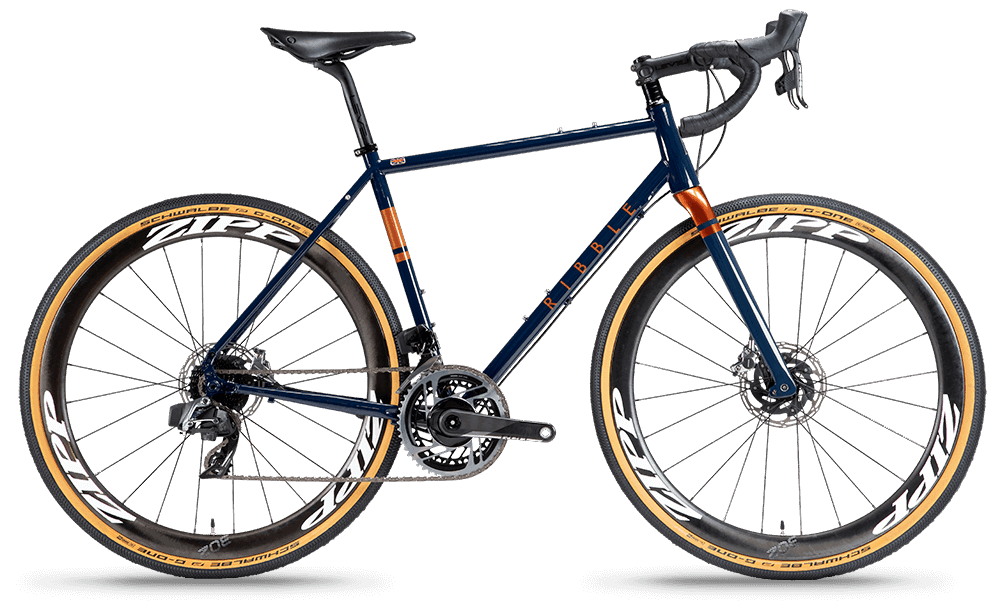

The CGR 725 is throughout modern steel road bike that melds classic retro styling with distinctly modern design features.

Constructed from 'Best of British' Reynolds 725 Steel tubing, the CGR 725 is a classic looking steel bike, but with a thoroughly modern twist. Reynolds steel tubing provides the comfortably springy ride quality that is so revered by many cyclists. Take a closer look though, and you will see some distinctly modern features within the framesets design.

Amongst others, this includes cutting-edge frame building techniques like seamless weld technology for unmatched strength and a premium finish. Other modern touches include; internal cable routing, tapered headtube and flat mount disc brakes fittings.

- Weight - Steel frames aren't as light as frames made from carbon, or alloy. Their popularity, instead, stems from the ability of the rider to simply sit in the saddle and rack up the miles with little fuss, maximum comfort and total satisfaction.

- Comfort - Similarly to Titanium, steel has a natural 'spring' which lends itself to long-ride comfort. It delivers a forgiving ride quality which results in reduced rider fatigue by way of vibration reduction.

- Durability - There are steel enthusiasts out there still riding about on frames that were manufactured in the '60s. Which certainly attests to their longevity. A high-quality steel frame that is adequately maintained can last a lifetime. Of course, steel frames are susceptible to corrosion. But only when they are not properly cared for. They do require a little bit of TLC occasionally to ensure that they remain in peak condition.

- Cable routing - When fitted with a double chainring gearing system, each cable is routed internally (with the exception of the rear hydraulic brake hose). Due to the narrower profile of the traditionally shaped (round) steel tubing, there is insufficient room to run every cable internally. If the bike is fitted with a single chainring (1x) system, it is possible to route ALL cables internally.

-

CGR AL

-

The CGR AL is extremely popular with daily commuters, with mudguard and rack compatibility and its ability to traverse a wide choice of terrains.

The CGR AL is constructed from oversized 6061-T6 heat-treated alloy. Rugged and robust, it's the perfect platform for exploring on or off-road. The versatility doesn't stop there, however, with discreet mudguard and rack mounts it also excels as an all-season commuter or multi-day bike packer.

- Weight - Second only to the CGR SL in terms of how light the frame is.

- Comfort - Similarly to its carbon sibling, alloy frames are incredibly stiff for enhanced power transfer. To add vertical compliance for improved vibration absorption and rider comfort the seat stays have once again been dropped.

- Durability - The 6061-T6 alloy is extremely strong and durable and can last many years. It doesn't however have the extended lifespan of steel or titanium. But if its care and maintenance are kept up to scratch, an alloy bike can last many years.

- Cable Routing - All cables are routed through the frame to give the bike its super-clean looks and sleek lines.

-

-

Want to know more about Ribble's range of electric bikes? Click here to find out more.

-

-

Looking for a bike and want to spread the cost? Have you considered the government-backed Cycle to Work Scheme? Find out how it works here.

-